Corrosion Resisting Aluminum 6063 Alloy T6 T651

Product Featureds

6063 aluminum is a widely used alloy in the 6xxx series of aluminum alloys. It is primarily composed of aluminum, with small additions of magnesium and silicon. This alloy is known for its excellent extrudability, which means it can be easily shaped and formed into various profiles and shapes through extrusion processes.

6063 aluminum is commonly used in architectural applications, such as window frames, door frames, and curtain walls. Its combination of good strength, corrosion resistance, and anodizing properties makes it suitable for these applications. The alloy also has good thermal conductivity, making it useful for heat sinks and electrical conductor applications.

The mechanical properties of 6063 aluminum alloy include a moderate tensile strength, good elongation, and high formability. It has a yield strength of around 145 MPa (21,000 psi) and an ultimate tensile strength of about 186 MPa (27,000 psi).

Furthermore, 6063 aluminum can be easily anodized to enhance its corrosion resistance and improve its appearance. Anodizing involves creating a protective oxide layer on the surface of the aluminum, which increases its resistance to wear, weathering, and corrosion.

Overall, 6063 aluminum is a versatile alloy with a wide range of applications in construction, architecture, transportation, and electrical industries, among others.

Chemical Composition

|

Chemical Composition WT(%) |

|||||||||

|

Silicon |

Iron |

Copper |

Magnesium |

Manganese |

Chromium |

Zinc |

Titanium |

Others |

Aluminum |

|

0.2~0.6 |

0.35 |

0.1 |

0.45~0.9 |

0.1 |

0.1 |

0.1 |

0.15 |

0.15 |

Balance |

Mechanical Properties

|

Typical Mechanical Properties |

||||

|

Temper |

Thickness (mm) |

Tensile Strength (Mpa) |

Yield Strength (Mpa) |

Elongation (%) |

| T6 | 0.50~5.00 |

≥240 |

≥190 |

≥8 |

| T6 | >5.00~10.00 |

≥230 |

≥180 |

≥8 |

| Product name | Aluminium Sheet / Aluminium Plate |

| Production Standard | ASTM, B209, JIS H4000-2006,GB/T2040-2012,etc |

| Material | 1000 2000 3000 4000 5000 6000 7000 8000 |

| Diameter | 5mm-2500mm or as the customer’s request |

| Longth | 50mm-8000mm or as the customer’s request |

| Surface | Coated, Embossed,Brushed, polished, Anodized,etc |

| OEM Service | Perforated, Cutting special size, Doing flatness, Surface treatment,etc |

| Delivery Time | Within 3 days for our stock size,15-20days for our production |

| Package | Export standard package: bundled wooden box, suit for all kinds of transport,or be required |

| Quality | Certificate of Test,JB/T9001C,ISO9001,SGS,TVE |

| Application | Construction filed, Ships building industry, Decoration, Industry,Manufacture,Machinery and hardware fields, etc |

Applications

AUTO FIELD

FORGING PRODUCTS

SEMICONDUSTOR

Our Advantages

Inventory and Delivery

We have enough product in stock, we can offer enough material to customers. The lead time can be within 7 days for stock materil.

Quality

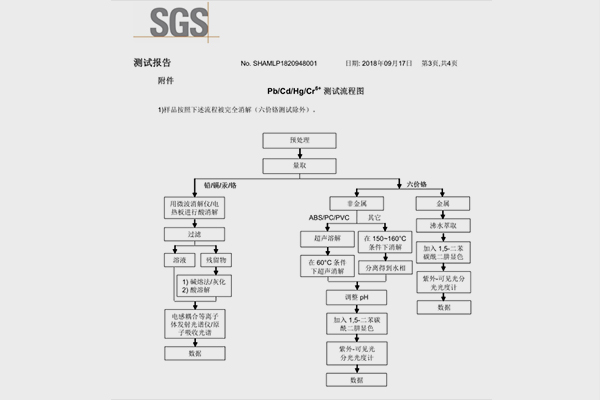

All the product are from the biggest manufacturer, we can offer the MTC to you. And we can also offer Third-Party test report.

Custom

We have cutting machine, custom size are available.

Product Packing

Corrosion Resisting Aluminum 6063 Alloy T6 T651 Related Video: