High definition 5000 Series Aluminum Tube - Pure Aluminum 1060 Sheet Aluminium Plate 1060 – Miandi

Aluminium / Aluminum 1060 alloy is a low strength and pure Aluminium / Aluminum alloy with good corrosion resistance characteristic.

Aluminium / Aluminum 1060 alloy can be hardened only from cold working. Tempers H18, H16, H14 and H12 are determined based on the amount of cold working imparted to this alloy.

Aluminium / Aluminum 1060 alloy is rated with fair to poor machinability, especially in the soft temper conditions. The machinability is much improved in the harder (cold worked) tempers. Usage of lubricants and either high-speed steel tooling or carbide are recommended for this alloy. Some of the cutting for this alloy can also be done dry.

Aluminium / Aluminum 1060 alloy is widely used in the manufacture of railroad tank cars and chemical equipment.

|

Chemical Composition WT(%) |

|||||||||

|

Silicon |

Iron |

Copper |

Magnesium |

Manganese |

Chromium |

Zinc |

Titanium |

Others |

Aluminum |

|

0.25 |

0.35 |

0.05 |

0.03 |

0.03 |

- |

0.05 |

0.03 |

0.03 |

99.6 |

|

Typical Mechanical Properties |

||||

|

Temper |

Thickness (mm) |

Tensile Strength (Mpa) |

Yield Strength (Mpa) |

Elongation (%) |

|

H112 |

>4.5~6.00 |

≥75 |

- |

≥10 |

|

>6.00~12.50 |

≥75 |

≥10 |

||

|

>12.50~40.00 |

≥70 |

≥18 |

||

|

>40.00~80.00 |

≥60 |

≥22 |

||

|

H14 |

>0.20~0.30 |

95~135 |

≥70 |

≥1 |

|

>0.30~0.50 |

≥2 |

|||

|

>0.50~0.80 |

≥2 |

|||

|

>0.80~1.50 |

≥4 |

|||

|

>1.50~3.00 |

≥6 |

|||

|

>3.00~6.00 |

≥10 | |||

Applications

Railroad Tank

Chemical Equipment

Aluminum Utensils

Our Advantage

Inventory and Delivery

We have enough product in stock, we can offer enough material to customers. The lead time can be within 7 days for stock materil.

Quality

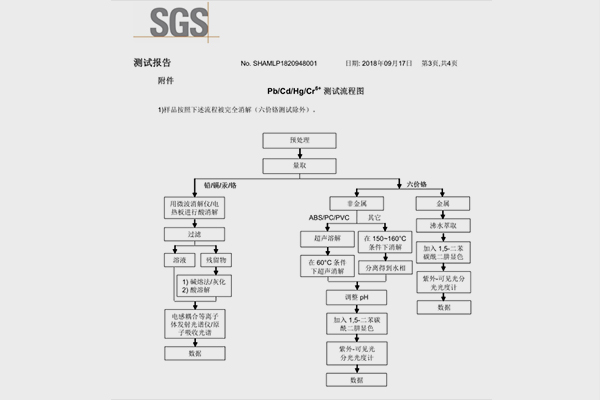

All the product are from the biggest manufacturer, we can offer the MTC to you. And we can also offer Third-Party test report.

Custom

We have cutting machine, custom size are available.

High definition 5000 Series Aluminum Tube - Pure Aluminum 1060 Sheet Aluminium Plate 1060 – Miandi Related Video: